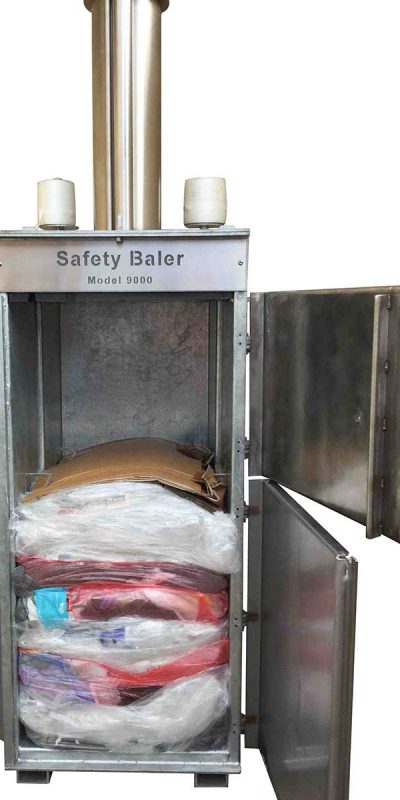

Hospitality and Store safety Baler

MODEL 9000

This small – medium sized pneumatic baler is brilliant for kitchens, retail stores, office buildings, residential towers and schools.

Because you have lots of cardboard, and lots of plastic bags full of mixed waste,

and you want to cut hauling costs / collection costs

The Safety Baler 9000 lets you crush and bale:

- bags of kitchen recyclables, including plastic bottles and steel cans

- bags of soft plastic wrap

- bags of general waste

- cardboard boxes

- or a mix of any of the above

Size

Footprint 34″ wide x 34″ deep / 85cm x 85cm

Height 103″ / 260cm

Weight 1080 lb / 490 kg

Maximum incoming air pressure – 101 psi / 7 bar

Compactor force – 7500 lb at 101 psi / 3.4 metric tonne at 7 bar

Bag size – plastic waste bags of 64 gallon / 240L size fit easily

Safe

Industry standard balers pose four risks to the machine operator.

The Safety Baler 9000 addresses each risk

- Operator crushed by the ram [crush plate]

To completely avoid this risk there are three things your operator cannot do, using a Safety Baler 9000

- start the ram while the door is open

[ie activate the crush plate while door is open and watch the ram descend and ascend] - open the door while the ram is active

[ie turn ram on with door closed, then open the door and watch the ram descend and ascend] - tie the bale with the door open and the ram engaged

[Danger Will Robinson Danger!. Operators should never be able to touch a ram under pressure]

- Operator crushed by heavy bale

The Safety Baler 9000 produces a maximum bale weight of around 130 lb / 60 kg which is a much lower weight than the 400 lb to 2000 lb bales that do cause serious injury. With practice the operator can create bales that weigh only 85 lb to 65 lb, if that is preferred.

- High pressure [1000+ psi] hydraulic hose failure – shoots very hot oil onto people and the environment

The Safety Baler has no hydraulic system and no oil. It is powered by a much lower maximum air pressure, at 101 psi. This lower pressure reduces operator risk in general

- Electric shock

The Safety Baler has no electric motor or electric wiring.

It need only be connected to a flexible air hose to operate it

We think these features add up to make this baler the safest medium sized baler ever offered

Smart

All balers face three operating problems.

The Safety Baler 9000 deals with each problem

- Spring back wastes time and energy

Much crushed waste will spring back once the crush plate is retracted Especially plastics, but cardboard will also. This reduces the volume of new waste you can load for the next crush cycle. It wastes the operator’s time – they can add less and less waste to each new crush cycle so they run more crush cycles than they should.

The Safety Baler restrains waste using a simple patented locking system that works - Uneven load bends the ram and piston rod

The fine print of the operating instructions for most balers will require the operator to ensure each new load of waste added to the baler is evenly distributed. If the waste load is spread unevenly in the baler, the descending ram can be bent, or pushed up hard against the closed front door of the baler to cause another safety risk when the operator opens the door. Also, the piston rod that bears down on that crush plate can bend or break due to an uneven load. Repairs are expensive.

The Safety Baler is the only baler in the world that holds the ram in its intended space via a slot on each side of the baler. This prevents ram bending, piston bending and forward pressure of the ram on to the door. - Hydraulic oil systems and electric motors need to cool down.

The industry standard hydraulic baler cannot be operated for lengthy periods of time because the electric motor and high pressure hydraulic oil both heat up to levels that will cause failure [and repair bills] The Safety Baler does not use hydraulic power, it uses compressed air / pneumatic power. A decent air compressor will run all day without issue.

Built for a long life

The Safety Baler 9000 is offered as two models, either:

- 9000HD – hot dip galvanized steel to give rust protection for an expected 20+ years, or

- 9000SS – stainless steel, grade 304 (18/10)

And the pneumatic cylinder is made from a heavy aluminum / aluminium which does not rust

Beware any baler made of mild steel, painted

For comparison,

the Safety Baler 9000HD model uses

– mild steel hot dip galvanized, plus 304 stainless steel for some parts that cannot be galvanized

– 1/5 inch / 5mm thickness minimum for body

– 2/5 inch / 10mm thickness for the ram